Stellarray’s digitally addressable x-ray sources (DAXS) have been developed for medical and other imaging applications, with an emphasis on stationary tomographic imaging. In stationary tomography the location of the x-rays is addressed electronically in the source rather than by physically moving an x-ray tube on a gantry, for tomography systems that are smaller, lighter, faster and more versatile than the current state of the art. The sources have been made at Stellarray’s lab using dedicated micro-fabrication, glass molding, vacuum system and radiation testing capabilities.

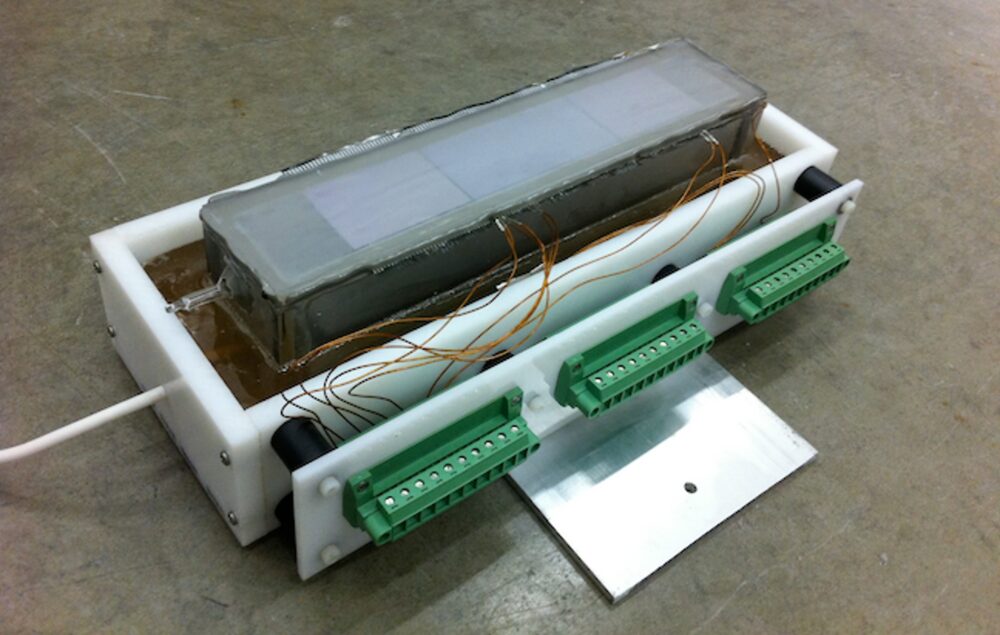

DAXS-1D uses a single linear array of field emission cold cathodes to address corresponding x-ray pixels (xels) on a shared anode opposite the cathode array. The anode is angled, to generate line-focus x-ray flux that emits out a window in the glass sidewall of the source. As in other Stellarray x-ray sources, the anode forms an integral part of the vacuum package, but has one side exposed to the external environment so it can be directly cooled by thermal transfer through a potting material in the casing or by close-looped fluid cooling. Various cold cathodes can be used in the emitter array. Stellarray’s preferred cathodes are proprietary multi-layer, triple-point edge emitters that can be made in a variety of configurations. The anode surface, such as W or Mo, is chosen for the spectrum needed in the application. The window is machined out the sidewall, or sealed into a window aperture and selected from common x-ray window materials. Filters and collimators are attached in front of the flux window. DAXS-1D can be made for voltages up to 160 kVp and anode currents of 50 mA.

DAXS-2D uses a 2D matrix array of field emission cold cathodes to address corresponding x-ray pixels (xels) on a shared anode opposite the cathode array. The anode is flat and the x-rays emit upwards from the surface, to pass through the cathode array and out the flux exit window the cathode array is built on. As in other Stellarray x-ray sources, the anode forms an integral part of the vacuum package, but has one side exposed to the external environment so it can be directly cooled by thermal transfer through a potting material in the panel casing or by close-looped fluid cooling. The top flux exit window is thin glass, sapphire or other low attenuation material. X-ray flux is collimated in the source, at the window or at the subject. DAXS-2D can be made for voltages up to 120 kVp and anode currents of 10 mA.

DAXS can be made in straight, curved or annular configurations. The high voltage power supply and digital electrical controls can be attached directly to the panel.