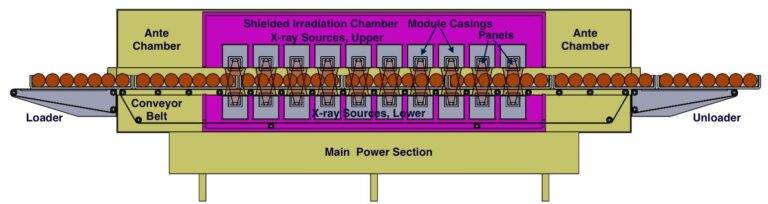

Stellar-Rad™ irradiation systems using customized flat panel X-ray sources are under development for the sterilization of agricultural, food and medical products. These are conveyor belt systems running product through multiple pairs of FPXS. Irradiation from both sides of the product and the movement of the product through the system ensure high dose uniformity. These systems can be scaled up or down to suit virtually any user throughout need by varying the number of panel pairs and the power to each pair. They will provide an attractive alternative to the cumbersome packaging and shipping steps now required for isotope or e-beam irradiation.

Stellarray’s focus now is on the “sterile insect technique,” in which the larvae of harmful insects are irradiated just enough to render them sterile, but leave them otherwise healthy, when released. This non-chemical technique has been successfully used to control a variety of insect pests threatening agricultural products and human populations. Stellar-Rad™ systems will replace radioactive isotope systems to help ensure public safety in the sometime remote locations where this technique is used.

Other applications will be in phytosanitary sterilization of crops so that they can be exported to larger markets, and in irradiating cannabis products to eliminate mold and other infestations that lower quality and yields. Stellar-Rad™ systems are electrical, meaning they have none of the radioactive isotopes that require complex and costly security measures. They can be used anywhere products are made, processed, packaged, tested or shipped, and they will fit seamlessly into existing process flows. Future uses of Stellar-Rad™ irradiators will be in medical device, pharmaceutical and cosmetics sterilization, where an in-line or terminal sterilization system can save the inventory costs now incurred with re-packaging and shipping to an isotope or e-beam sterilization facility.

To inquire about Stellar-Rad™ irradiator development, Please send email to info@stellarray.com