Soon after the discovery of x-rays, and the realization that they can alter material and biological properties, people tried sterilizing food and other agricultural products with them. Traditional x-ray tubes were never very successful at this, since they use a single cathode that make a single x-ray spot on the anode (or track on a rotating anode). Most of the power put into an x-ray tube is converted to heat, and managing the heat on the anode spot proved to be the limiting factor.

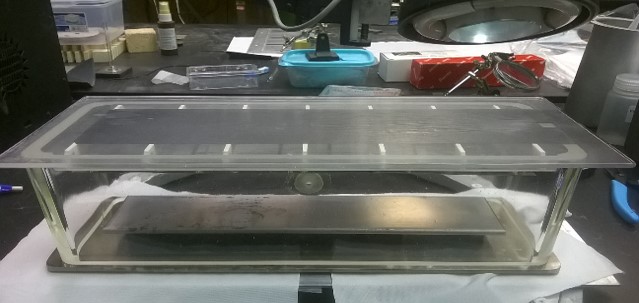

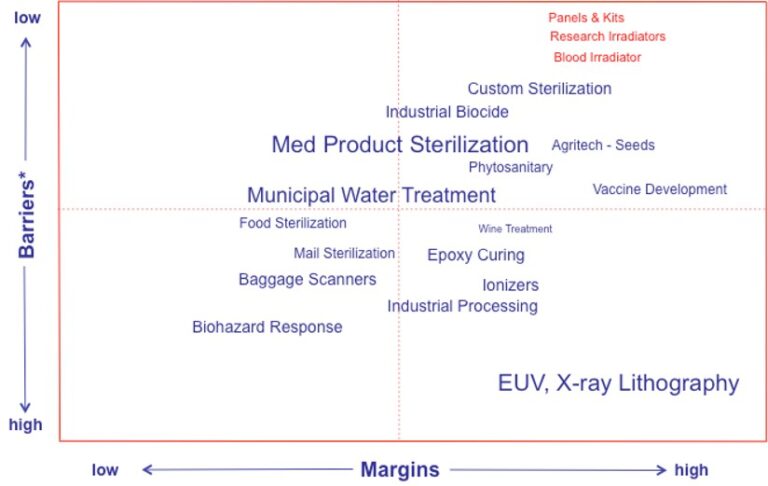

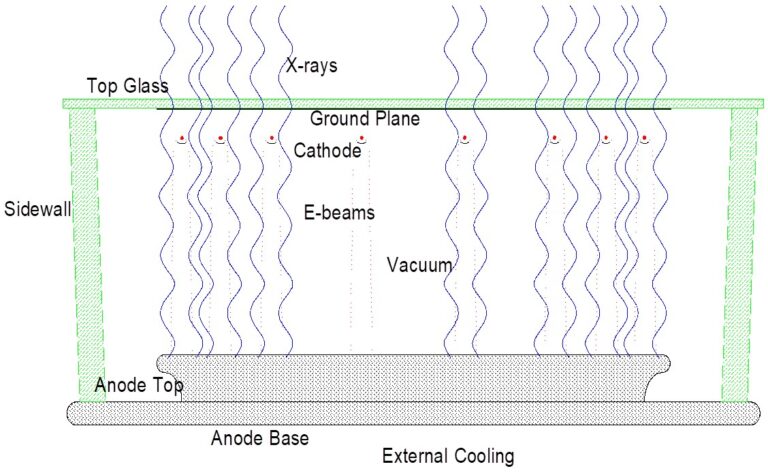

Stellarray’s Flat Panel X-ray Source (FPXS) solves this problem in several ways. By using a cathode array to generate the electron beams that accelerate at high voltage across vacuum to hit the anode and make the x-rays, power can be spread across the anode by several orders of magnitude compared with a tube. FPXS has one side of the anode facing the external environment so it can be directly cooled with circulating fluids or forced air. FPXS doesn’t have the “heel effect” of an x-ray tube, which increases source efficiency, and the source area can be matched to the irradiation target area, which increases system efficiency. All this makes FPXS more power efficient than x-ray tubes, for operation at lower power consumption and higher x-ray flux output over longer periods. Stellarray is using FPXS in select applications with low barriers to entry and high gross margins, but we can make them for some other applications.